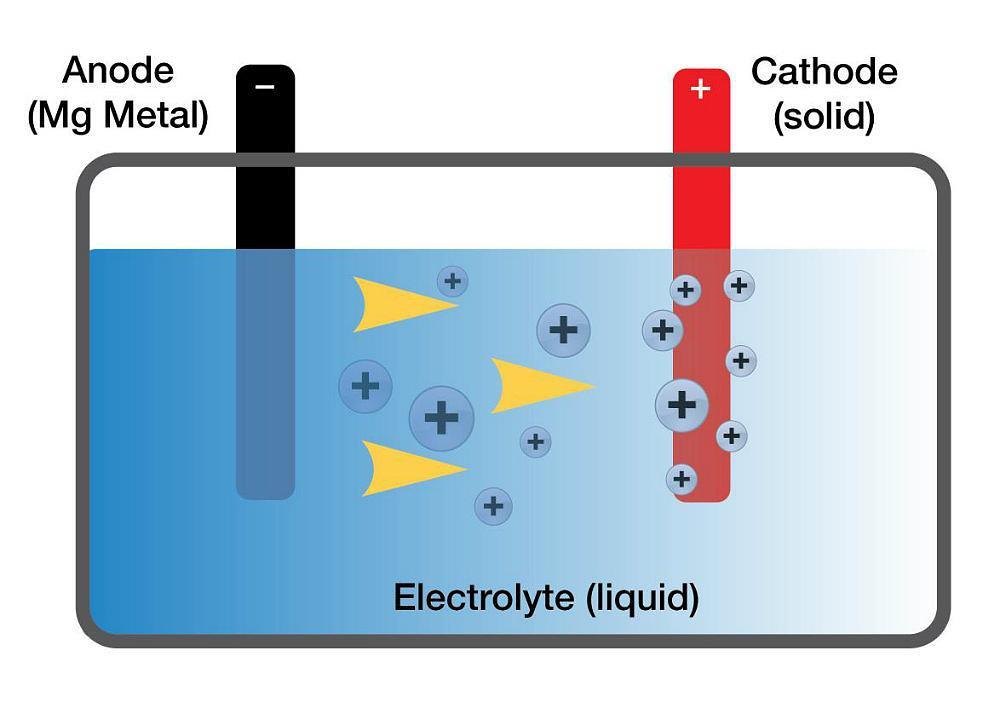

It is making energy production from intermittent renewable energy sources such as wind and solar replace fossil fuels more viable. Further advances in nickel-containing battery technology mean it is set for an increasing role in energy storage systems, helping make the cost of each kWh of battery storage more competitive. For a device like an electron tube that absorbs. The separator is porous to enable the transport of lithium ions and prevents the cell from short-circuiting. The standard convention is that the electrons enter a device through its cathode and leave through its anode. The electrolyte can be liquid, polymer, or solid.

The anode is usually made out of porous lithiated graphite. In this process route, the active material is created from. The major advantage of using nickel in batteries is that it helps deliver higher energy density and greater storage capacity at a lower cost. The lithium ions therefore move through the electrolyte and intercalate in the crystal structures of the two anode and cathode electrodes (structures which. The cathode is made of a composite material (an intercalated lithium compound) and defines the name of the Li-ion battery cell. One option for the synthesis of cathode and anode materials is the so-called solid-state process.

#Battery anode and cathode portable

Around the same time, the first commercial applications for Li-ion batteries emerged, initially in camcorders and eventually finding their way into smartphones, laptops and the numerous other portable devices we now take for granted. The mid-1990s saw the first significant use of NiMH batteries in vehicles in the Toyota Prius.

Their adoption in power tools and early digital cameras revealed the potential for portable devices, changing expectations of how we work and live. Nickel (Ni) has long been widely used in batteries, most commonly in nickel cadmium (NiCd) and in the longer-lasting nickel metal hydride (NiMH) rechargeable batteries, which came to the fore in the 1980s.

0 kommentar(er)

0 kommentar(er)